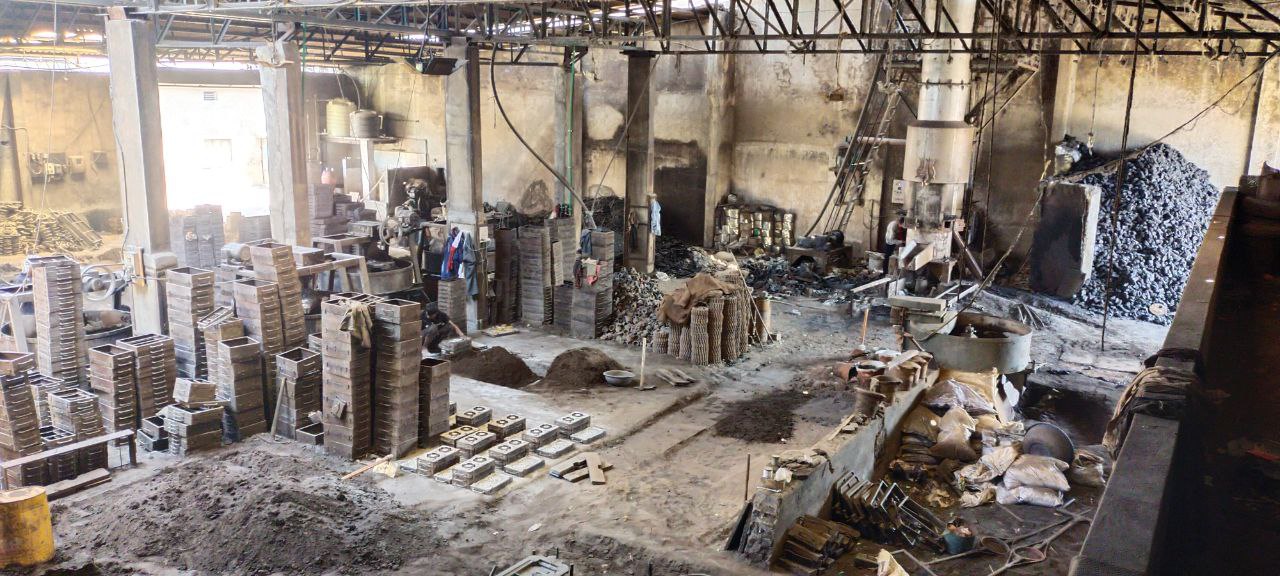

Process

During the casting process, we follow a strict Quality Control procedure to ensure quality casting.

We perform several critical steps for quality casting before the casting process begins. For example, raw materials are checked, sand mixture is tested, modulus and cores are examined before the casting process begins. At the end of the casting process, we finish the product with a final inspection procedure.